GCHI Blog

Heritage Lottery Fund award to restore the Woolsthorpe Flight

NOTE: Both lock 14 and 15 are now restored and Grantham Canal Society is in the early stages of restoration of lock 13.

The Grantham Canal Heritage Initiative (GCHI)

A working partnership between the Grantham Canal Society and Canal and River Trust

With support from the Waterway Recovery Group

Following the success of this bid, £830,800 has been awarded to the project to restore Locks 14 & 15

NOTE: Both lock 14 and 15 are now restored and Grantham Canal Society is in the early stages of restoration of lock 13.

Follow us on Facebook and Twitter for daily updates about the Grantham Canal, including GCHI progress.

Regular updates also appear in our free monthly email newsletter ‘Bridge’. Request this and read back copies on our homepage.

You may also like to read this blog by Kathryn from the Canal and River Trust: Canal and River Trust blog

22nd September 2021

Author & upload TJ

That just about wraps up the National Lottery Fund supported ‘Grantham Canal Heritage Initiative’ to restore Locks 14 & 15.

But that’s not the end of the story – attentions are now turned to the remaining two locks in this flight of seven; 12 & 13. Funding is presently being sought for these. It maybe we approach these two remaining locks as separate entities, Lock 13 being the next, as we work our way downwards through the flight.

This five year project has been so rewarding for all those involved – it’s been hard work – no denying! But the sense of accomplishment is immense.

But Saturday 18th September was a time for celebration in the form of a BBQ and something ‘interesting’ by way of beverage 😉 This informal gathering was enjoyed by our volunteers, joined by Grantham Canal Society members and invited guests who’ve played role in bringing this iconic project to its successful conclusion.

Funding wheels move so slowly, which is a frustration when we have the bit between our teeth. With a following wind, it maybe two years before set foot on Lock 13. We’re not short of projects in the meantime – watch our social media for progress of the barge slipway reconstruction, raising of Denton weir, culvert repairs and the ‘Dry Section Project’, having made a tentative start earlier this year.

8th August 2021

Author & upload TJ

A significant day, not only for Lock 14, but also in the life of the Grantham Canal and the heritage of the region, both built and ecological.

August 3rd was Media Day, when the completed Lock 14 was celebrated with the public at large via the medium of printed press, radio and television.

Hard hats, hi-vis, mud, sludge and endless bricks are now behind us – until the restoration of Lock13 begins – but for now, it’s a time of celebration, mixed with an element of reflection, as each one of our volunteers, looking back at the enormity of the job, can’t perhaps quite believe it’s finished!

Each one of us, who played a part, whether working on the lock itself, engaged in fundraising, baking cakes, running boat trips – remember that £95,000 we needed to raise in match funding – can feel proud of this monumental achievement! The seemingly endless meetings and admin is largely behind us for Locks 14 & 15. No time for rest though, as our fundraising team are busy seeking funding for Lock 13, the penultimate lock in this flight of seven.

A further celebration is to be arranged so that all volunteers, Society members and the wider community can join together with us by way of a massive thank you – we could not have done it without any of you.

This project has been a working partnership between the Canal and River Trust and the Grantham Canal Society, with valuable support from the volunteers of the Waterway Recovery Group.

Richard Parry (L), CRT Chief Exec, Mike Stone (centre) Chairman, GCS, His Grace The Duke of Rutland, GCS Patron (R)

Some of the volunteers who worked on the project, with site supervisor Mark, front row 3rd from left

Grantham Canal Society Patron The Duke of Rutland (L), Phil Mulligan, CRT East Midlands Regional Director (R)

First boat for 90 years prepares to leave Lock 14

Karen Rice, CRT, Project Manager for the rebuild of Locks 14 & 15 talks to BBC Radio Lincolnshire

18th May 2021

Author &

upload TJ

Levelling, spreading topsoil, seeding and planting sums up the last few weeks. Over 200 native trees and shrubs have been planted at Lock 14 alone, with more at Lock 15. I don’t know how closely the seeding followed the draft plan, but fingers crossed (due to the exceptionally dry weather after sowing), we shall see emerging, a wide variety of native wild flowers and grasses.

Some of our first visitors lockside as the fencing was removed

The towpath is now open! Visitors are able to view the work of our volunteers, who were supported for many weeks over the last five years, by volunteers of the Waterway Recovery Group. The project has also been used in the training of Canal and River Trust Heritage Trainees.

Contractors, W Squires, have been engaged in raising the offside bank between Lock 14 and Bridge 60. Although this work was well within the capacity of our trained volunteers – time scales weren’t! The project end date looming, expedience was the governing factor.

The Lock 14 works compound is to be retained for when work can begin on the restoration of Lock 13. As mentioned in the previous entry, the Expression of Interest was submitted to the National Lottery Heritage Fund. It was requested we review parts of our submission and re submit in December 2021.

For those unable to visit, or just like a birds eye view, we thank Colin for this drone footage:

Entry 10th March 2021

Author & upload TJ

Volunteers engaged in bank levelling at Lock 14

Back to work at Lock 14 this week following Lockdown 3. There’s talk of this being the last national lockdown in this worldwide Covid-19 Pandemic. Let’s hope we begin to return to a degree of normality during 2021, and that mutated strains of the virus can be batted away from our shores.

Still a few jobs to be done around the site, plus reinstatement around Lock 15, before we wrap the Lock 14&15 element of the project up.

Funding now needs to be sought to restore the remaining two locks in the Woolsthorpe Flight. We’re currently preparing the ‘Expression of Interest’ to the National Lottery Heritage Fund for support in restoring locks 12&13. To continue working in reverse order down the flight, the next to receive our attention will be Lock 13, which looks to be a classic restoration, rather than the rebuild we’re expecting Lock 12 to be. Due to space constrictions at Lock 13, we’re to continue using the Lock 14 works compound. Both locks being close to each other makes this workable.

Some ‘community element’ to tell you about! Rosemary, who delivers the majority of the Society’s talks, gave a PowerPoint presentation via Zoom, to Vale of Belvoir Probus recently. Otherwise, the community element has largely stalled for 12 months due to the pandemic.

Entry 9th December 2020

Author & upload TJ

In the midst of the Covid-19 pandemic, this is still having an impact on working practices throughout the Society’s activities. With the exception of ‘same household’ boat trips on one day, none of our fundraising events were able to take place this year. With news of a vaccine having been developed, immunisation is about to begin. Let us hope 2021 will bring with it some degree of normality.

So despite the best efforts of Coronavirus to thwart us, Lock 14 did get finished! Volunteers are still on site engaged in the many jobs around the periphery of the site, including the provision of lock moorings.

240 trees have been planted as part of the ecological reinstatement. These include Alder, Downy Birch, Goat Willow, English Oak and Field Maple.

Conditions underfoot have been challenging, with the wet sticky clay often adding 10 lbs to each boot!

Entry 10th October 2020

Author & upload TJ

Bottom Gates Lock 14

Back on site for some weeks, both top and bottom gates have been fitted. Canal and River Trust gate technicians led this installation, assisted by GCS volunteers. Volunteers have been busy fitting lock and gate furniture.

Like all jobs, the showy aspect of lifting the gates into position over, leaves a myriad of work to be done around the site. Volunteers have been engaged in everything from fencing, pointing stonework and fitting bollards to lock moorings.

Covid-19 is still prevalent within the community – the world! Work is being organised in a socially distanced way.

This same works compound is to be used for the restoration of nearby Lock 13. Stock fencing on the approach road is being renewed in view of this.

Lock 15 seat incorporating engraved bricks

At Lock 15, the lockside seat has been installed, along with the engraved bricks. These bricks are the conclusion of public donations from our Buy a Brick scheme, raising funds for the project.

Entry 27th June 2020

Author & upload TJ

I don’t know how history will report Covid-19, but it’s certainly thrown a spanner in the works at Lock 14! The lock gates were due to have been installed at the end of May, and we’d likely have been thinking towards a celebration of another successful rebuild, following on from that of Lock 15.

As it is, the site’s been mothballed for many weeks during the government introduced ‘Lockdown’. However, we’re currently working with CRT, for a socially distanced return to work very shortly. The original September deadline for completion of this five year project to rebuild/restore Locks 14 & 15, has naturally had to be extended.

Not part of this project, but with two more locks to restore in this flight of seven, we’re currently preparing the bid to the National Lottery Heritage Fund, for support in the restoration of Lock 13.

Entry: 2th February 2020

Author & upload TJ

With brickwork of Lock 14 to full height, work has focused on the coping stones and the myriad of jobs around the periphery of the lock.

There has been a delay in providing the anchor blocks; the quarry having encountered a poor seam, as mentioned in the previous post. These are still not on site.

Waterway Recovery Group volunteer working on the permanent bywash

In the initial part of the Lock 14 works, a bywash was provided – largely by volunteers of the Waterway Recovery Group. This bywash was required allow canal water to bypass the lock, once the dams were in place to isolate it before work could begin. This bywash was a feat of engineering in itself, as it circumnavigated the works by a wide berth. This bywash was temporary. With the lock chamber largely finished, volunteers are working to provide the permanent bywash, by a more direct route closer to the lock.

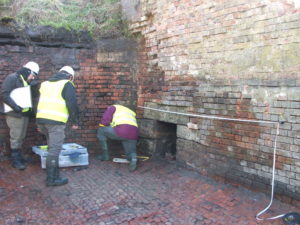

Lock approach walls are being restored/extended. Ground paddle drop chambers and ‘letter box’ culverts restored. Archaeologists from Mercian Archaeology have been on site, recording and overseeing the removal of the original wooden cills and forebays.

Prolonged wet weather makes for challenging working conditions

Underfoot conditions on site have been challenging for many weeks, due to prolonged wet weather.

Lock gates are scheduled to be fitted at the end of May.

Contractor Squires, have dredged the section above Lock 14, as far as Stenwith Bridge (60). Squires previously dredged from Bridge 60 to L15 and along the Half Mile Pound. So we have a dredged section from L16 through to L14.

The Community element of the project is continuing after the Christmas/New Year break, with talks to groups, a Learning Team visit to Harby School with activities to compliment their project about bridges. Our Events Team have a full program planned again for the coming year.

Entry: 15th October 2019

Author & upload TJ

There’s more to this lock restoration project than bricks and mortar – although it has to be said – these do play a significant part! We’ve been full on running events throughout the summer, culminating in our annual Discovery Day on the 13th October. With £95,000 in match funding to raise, these events are an important aspect of the project – and the reason for this rather late update!

Lock 15 Official Opening

Few, who are following our progress, will have missed the fact that Lock 15 is now complete! The official opening took place under a blue sky on Friday 13th September – lucky for some! Local, regional and national press attended and the occasion was shown on regional TV.

Lock 14 continues to grow. Chamber walls are at full height and we’re awaiting delivery of the anchor stones – to which the gate anchors are fitted. These huge stone have been delayed due to the quarry hitting an defective seam in the strata.

Volunteers of the Waterway Recovery Group have been with us for almost the whole of July, and are to return again this weekend, 19th October for a week. Their task is weather dependent, and I understand will either be working on Lock 14 approach walls/moorings or raising the bank in areas which have been identified along the half mile pound.

Lock 13 is now entering the picture. The current project allows for the engineering survey work to be carried out on this lock. Some preliminary sample drillings were taken last week. We don’t, at present have the funding to restore this lock – but we are currently in discussions with the National Lottery Heritage Fund.

Entry: 6th July 2019

Author & upload TJ

Concrete pour 26th June 2019

Lock chamber walls continue to grow 600mm at a time. They currently stand at 3m, with approx. 1.4m to go. The weather has been largely kind, but a week of incessant rain during June did require the most recent concrete pour to be rescheduled. Volunteers now have a view! Having built their way out of the clay sump, working conditions are becoming drier underfoot.

Thank you to Sea Lane Media for this image

The half mile pound between Lock 15 and 16 has now been dredged. This will allow for a boat navigate through previously restored locks, and to be worked through the recently rebuilt Lock 15 on the occasion of its official opening. We’re currently awaiting confirmation from the Canal and River Trust, our partners in this project, for confirmation of this date.

The guys of the Waterway Recovery Group will be arriving at their accommodation as I write. We look forward to welcoming them on site next week, where they’ll be with us for three weeks – different team each week. Some of the group will be working on the reinstatement of the Lock 15 works compound.

Our Events and Learning Teams continue to fulfill their commitment to the HLF, and have recently organised a successful Schools’ Week. Many fundraising and awareness raising events continue to be organised. These contribute to the Society’s commitment in raising £95,000 match funding over the five year duration of this project.

Entry: 15th April 2019

Author & upload TJ

Shows temporary wooden struts fitted across the lock chamber to support the walls whilst the concrete is poured.

A different approach, with experience gained from the rebuild of Lock 15, is being adopted for rebuilding of Lock 14. We’ve dispensed with firstly building the walls with concrete blocks – deciding to go straight in with the bricks. The lock walls are built up 600mm at a time, the concrete is poured in to that level, before building the wall up another 600mm, and another concrete pour. The weight of concrete is considerable – its weight would likely push the newly built walls over until it set. The concrete block walls of L15 were to prevent this happening. Without the blocks, wooden struts are placed between the lock chamber walls to brace the brickwork. This method of construction has proved beneficial in saving time and materials.

The invert (lock bottom), was also found to be in very poor condition. Following consultation with the heritage advisors and works engineers, the invert has been concreted. Mercian Archaeology, with volunteer input, have recorded original structures.

You know you’re making progress, when scaffolding is needed to reach working height.

Chamber walls are progressing, and scaffolding has now been erected in the lock chamber to raise the working height. Volunteers have also been restoring the lock approach walls.

The community element of the project remains busy, with events, open days, youth group visits and a Schools’ Week planned at the canal depot.

Similar to the five benches to be associated with circular walks based on the canal.

The interpretation element to provide five engraved benches depicting a map and points of local interest, although fairly advanced in the planning, is currently stalled due to a staff vacancy within the Canal and River Trust.

Entry: 17th January 2019

Author & upload TJ

Access road, bywash, dams installed and the lock pumped out, work could begin to clear the extensive amount of rubble and silt from the lock chamber.

Stock fencing and gating along the temporary access road to the work site

This lock was found to be in poorer condition than even that of Lock 15. The remaining (towpath side) wall and the lower thrust block/quadrants were all found to be unsound and required taking down completely. With Lock 15, although requiring extensive work, the lower thrust blocks were restorable.

Demolition of unsound structures

The invert has also been found to be in poor condition, again, unlike that of Lock 15.

Student from Harlaxton College lending a helping hand brick cleaning

Recovered whole bricks are being cleaned up for reuse; broken bricks/rubble removed from site.

The site is now ready for the first concrete pour.

Let rebuilding begin!

Entry: 5th November 2018

Author & upload TJ

With Lock 15 consigned to history, we’ve now taken root at Lock 14.

Volunteers of the Waterway Recovery Group building the bywash Lock 14

GCS volunteers building storage bays for building materials

The Waterway Recovery Group have held five, week long canal camps at Lock 14. Working alongside Grantham Canal Society volunteers, this has cumulated in construction of site access and works compound being established. Storage bays for loose building materials and the bywash have been built. The lock has now been isolated with provision of dams either end, and work is well advanced in dismantling what remained of the unsound lock chamber walls.

Lock 14 before work began

Two groups have visited over recent days/weeks to view the works: Walkers from the South Lincs Walking Festival and members of the Stratford upon Avon Canal Society.

Lock 15 complete

The gates were made at the Canal and River Trust workshops at Stanley Ferry – these are the top gates

Dredging and some bank raising work is planned on the half mile pound between locks 15 and 16 over the winter months. This will extend navigation as far as Lock 15.

An official opening will take place during 2019, the date yet to be decided upon.

Entry: 16th July 2018

Friday the 13th – of all days – was the day we’d all been waiting for: upper stop planks were removed, allowing the lock to be filled. A momentous occasion – after three years, working five days a week with almost all volunteer work on site. We also thank the Waterway Recovery Group for their valued input, and the Canal and River Trust, as predominant owners of the canal, we could not do this work without their approval and support by way of project management.

…and it couldn’t have happened without the support of the Heritage Lottery Fund.

Entry: 1st July 2018

Author & upload TJ

With the lock moorings completed, new top and bottom gates have now been fitted and we look forward to removing the stop planks, perhaps this week, returning the lock into water.

The paddle gear has been fitted to the gates and ground paddle sluices. Work continues fitting lock furniture, i.e. hand rails, balance beam steps and handles etc.

An opening day is planned, but as yet, we don’t have a date – suggest you keep a watchful eye on our Twitter and Facebook pages for this.

Work will soon commence on Lock 14. The grass has been cut in the field along the line of which the temporary access road is planned, and the archaeological survey completed. Mercian Archaeology hope to return to the site at a later stage to do a more in depth survey with community involvement, as there is some interesting archaeology nearby. Mercian are the company who’ve recorded Lock 15 throughout.

Entry: 11th March 2018

Author & upload TJ

Canal in water up to the stop planks, with new moorings under construction

Stop planks have been fitted to the upper end of the lock, the temporary dam removed, and the canal is now in water up to the stop planks. Lock moorings are currently being built at the top end of the lock.

WRG NW, Forestry Group and GCS volunteers clearing trees along the half mile pound

Waterway Recovery Group (WRG) North West, Forestry Group have recently been with us, dealing with the fallen trees in the half mile pound. There is still much to do, and WRG’s Bit in the Middle Group are visiting again during March, to continue with this work – assisted again by Grantham Canal Society (GCS) volunteers.

The scrub on the offside bank of the half mile pound had previously been cleared by GCS and corporate groups from businesses. All this work is in readiness for dredging and bank raising work, between our newly restored Lock 15 and the three previously restored locks in this seven lock flight.

The new lock gates are currently being made at the Canal and River Trust’s workshops at Stanley Ferry – volunteers are to visit to see this work in progress.

More clearance work has been done in preparation as we eagerly await to start Lock 14, when permissions for the access road are finalised.

Events Team Training Day

Meanwhile, the community element of the project is approaching its busy time of the year – although it’s not been completely dormant throughout the winter – our speakers delivering a number of illustrated talks, and the Events Team already having some shows under their belt.

20 volunteers recently attended a successful events training day at our canal depot, Woolsthorpe.

Tempted to ask for suggestion for this caption – whatever they’re up to – they’ve been rumbled…

Volunteers, Ralph, John and Tony having fitted the lower stop planks – yes, that is a sheet of ice Tony is holding!

Entry: 29th January 2018

Author & upload TJ

With Lock 15 chamber complete and lock moorings installed at the bottom of the lock – it was time to install stop planks and remove the lower dam to allow the water back – a significant milestone!

Lower dam removal

Work is continuing at the top of the lock to install lock moorings here.

It’s worth noting that historically, lock moorings did not exist on the Grantham Canal, but are a requirement today.

Our Saturday Workparty have been working for a number of weeks, with help from corporate visits by Experian, to clear scrub from the offside bank along the half mile pound. This is in readiness for bank repairs and dredging to take place between the previously restored Lock 16 and newly restored Lock 15. Depth gauging has been carried out and calculations have indicated the quantity of silt removal required.

A significant milestone – water being allowed to return up to the lock since work began August 2015

As part of our commitment in raising almost £100,000 in match funding for this project, we have started a Dredging Fund.

Donations to the fund will count towards this commitment and, hopefully, the fund will continue to grow, allowing further much needed dredging elsewhere along the canal.

You can donate to this fund on our homepage – without your support we couldn’t continue with our work – that’s the harsh reality.

Volunteers continue to work every day Monday to Friday on the project – different team each day. It’s a good time to get involved, as they’ll soon be moving down the flight to Lock 14 🙂

The lock gates are expected to be built at the Canal and River Trust’s Stanley Ferry workshops during February.

Entry: 19th November 2017

Author & upload TJ

It’s always a pleasure to welcome volunteers of the Waterway Recovery Group, who were with us for almost four weeks in August – we thank them for their support on this project 🙂

Canal and River Trust Heritage Trainees have also worked on the project, gaining valuable experience.

Grantham Canal Society volunteers continue to work every day Monday to Friday – different team each day. Some of our volunteers are in more than one team – so much is their enjoyment and satisfaction in the work they do.

So, after the ‘showy’ part of the job; pouring concrete and laying new bricks, we came to the slow, painstaking part! This is – or should I say was, restoring the thrust blocks and wing walls. This part of the job is now complete. Thrust blocks are the four corners of the lock, which were deemed restorable, and were left standing when the lock chamber walls were taken down brick by brick.

Thrust blocks are the four corners. The top thrust blocks (right of picture), are particularly complex, as these contain the water management system of culverts, drop chambers and paddles.

This November 2017 picture shows the completion of the chamber walls, thrust blocks and wing walls, with lock moorings to the left.

With coping stones fitted, work is continuing on building retaining walls – these are the sloping walls either side of the lock.

These are necessary as part of the landscaping, due to the requirement of constructing lock moorings – and the grass banks not coming to the water’s edge.

Further work is required to wing walls and to provide lock moorings at the top end of the lock.

Dredging

Dredging is required between this lock and the previously restored three locks in the flight. Depth testing has been carried out along the half mile pound, to establish the amount of silt requiring removal – and to arrive at costings.

To this end, we have launched a Dredging Campaign – details of how you can support us in this, can be found on our homepage.

Industrial Archaeology

Mercian Archaeology, with assistance from volunteers, have carried out recording of the structure throughout the project. Detailed records continue to be produced.

Community

This is an important element of the Heritage Lottery Fund award and part of our commitment.

Our Events Team have had a very busy season of events. Not only have they attended many shows throughout the summer, they’ve organised events at our canal depot at Woolsthorpe by Belvoir and a number of guided tours around the lock restoration site – follow us on Facebook, Twitter – see our newsletter and website diary, so as not to miss these in 2018.

Excited duck launchers in the ‘hilarious’ Dirty Duck Race!

Our annual Discovery Day was again a huge success, both in raising awareness and much needed funds – we all had a fabulous time! Over 700 of you visited us on the day; £2,360.50p was raised for the cause. Thank you!

Our speakers continue to be busy delivering their illustrated talks about the canal and other subjects too! Whatever the topic, speakers donate their fee to society funds. You’ll find the list of topics on the diary page of our website.

Our Education Team have visited a number of schools this year. They have recently joined forces with the Canal and River Trust ‘Explorers’. This enables them to deliver well resourced and wide ranging activities to schools and youth groups along the canal corridor. They welcome more volunteers to this fledgling team.

Training is provided by the Canal and River Trust, and DBS checking is included.

To enquire about any of the wide ranging volunteering roles, please visit our homepage.

Thank you for taking an interest.

Tony J

Entry: 21st August 2017

Author & upload TJ

When work is straightforward, it’s easy to make an impression – to look back at the end of the day/week, and see real progress. This was the case with rebuilding the lock chamber walls. Pouring concrete, laying new bricks and blocks of uniform size makes for rapid progress.

Rapid? We’re just into our third year in restoring this lock. Those of you with some knowledge of the canal, will know the whole 33 miles were built in just four years!

How were those navvies able to achieve this? Which ever way you look at it – it was a remarkable achievement. There were hundreds and hundreds of them of course, and boy, could they show you a day’s work! They were well paid and, they were skilled.

We do have some young volunteers, but it has to be said, many are of a certain age – I doubt many would cope with digging out, with pick and shovel; 12 cubic yards a day – every day – as navvies of old were not only capable of, it was expected.

A press cutting from (I think) The Stamford Mercury, the oldest newspaper in the country, told of a riot, when two navvies from the Grantham Canal were ‘locked up’.

Now, that’s 24 cubic yards of soil and rock each day which isn’t being dug. Add to this the camaraderie which existed between these largely lawless men – they were having none of it! So 200 of their workmates – went and got ’em out!

I don’t think we had a single bricklayer among our volunteers when we started – we’ve trained people on the job. We’ve also trained people in the use of heavy plant. These now have a qualification which is relevant on any construction site in the country.

We constantly have to liaise with our funders, heritage advisers, ecologists and our partners in the project; owners of the canal – the Canal and River Trust.

Locks are big sturdy things – but they were built to a price. The very clever design – using counterfortes to stabilise the lock chamber walls for example – meant fewer bricks would be needed. Over 200 years later, it is these counterfortes (think buttresses), which had failed on Lock 15.

We’ve used a different approach to rebuilding the lock chamber walls – it will look traditional when finished. If the canal’s design engineer, William Jessop, had employed this more substantial method of construction – the canal would never have been built – his price wouldn’t have been accepted!

Note the finger marks in the bricks. Thank you to CRT Heritage Trainee Iona for spotting these

The original bricks for these locks, bridges, lockkeepers cottages, and canal workshops at Woolsthorpe, were made in a brickworks by the side of the canal here. Women and children were often employed in this activity. It has been interesting to discover the finger marks of, possibly a child, in some of these bricks. These finger marks, likely formed, when handling the wet clay following molding, en-route for the kiln.

Rebuilding the locks is a major part of the project, but it’s not the only part. A requirement of the Heritage Lottery Fund – without whom we wouldn’t have been able to do the work – is community work. We’ve always been keen to do this – we need to demonstrate that we are doing even more!

Volunteers are involved in giving illustrated talks, and they visit schools and youth groups with canal related activities.

Volunteers have also been working with outside providers on a project to improve interpretation along the canal. This will take the form of four new benches, each with a carved map of the canal and local information. Each bench will be associated with a circular walk, which will have an accompanying leaflet, with information on our website too.

industrial archaeology recording assisted by volunteers

The archaeology of the lock structure has been recorded throughout.

archaeology recording in warmer weather

Navvies of 200 years ago didn’t have to do any of this stuff!

We are pleased to welcome the Waterway Recovery Group to Lock 15 again – here for four weeks, and are on site as I write in August. I started my post by talking about making rapid progress – we’re now at the stage where we’re restoring the bits of the lock which were left standing: wing walls, thrust blocks, ground paddle chambers etc. This is the type of work which absorbs the time, when, after a day’s work, you look back at the little you appear to have achieved.

I’ll leave you with some pictures of the Waterway Recovery Group at Lock 15 Aug 2017.

rebuilding one of the wing walls

posed? of course not!

…and, before I find my bike tyres deflated – I must fly the flag for our own Grantham Canal Society volunteers who work every day, Monday to Friday on this project 🙂

Author & upload TJ

Entry: 13th December 2016

Awaiting the last brick to be laid in rebuilding Lock 15 chamber walls – hope it fits…

Good reason for jubilation – the final brick was laid yesterday on Lock 15 chamber walls! Our volunteers have been working every day, Mon – Fri, for just over a year. For around half of this time, they were occupied in taking down the two chamber walls, upon finding they were beyond restoring. The walls have been rebuilt using concrete block/poured concrete supporting structures – lined with Birtley Olde English bricks. These will give an authentic look to the lock when work is finished.

Volunteer Richard is given the honour of tapping the last brick into place – looking in is Iona, Canal and River Trust, Heritage Trainee

There is still some work to be done in restoring the ‘thrust blocks’ and ‘wing walls’. The thrust blocks were left standing, deemed restorable by the engineers. Thrust blocks form the four corners of the lock, it is these which take the strain of the lock gates. The upper pair of thrust blocks also house the ground paddle culvert/chamber, used for filling the lock. Emptying the lock chamber is via paddles (sluices) in the lower gates. Wing walls are the curved walls which form the entrance and exit of the lock.

We particularly wish to thank the volunteers of the Waterway Recovery Group. Their input has helped us enormously in reaching where we are today.

The Canal and River Trust too, for their ongoing support, both on site and in project management – ensuring we adhere to the requirements of the Heritage Lottery fund, without whom, this important part of our industrial heritage would still lie in a decayed state.

Entry: 23rd November 2016

Author & upload TJ

We were pleased to welcome the Waterway Recovery Group on site at Lock 15 for almost the whole of July. Along with our own volunteers, much was achieved.

offside chamber wall full height

Nearing the end of November, we have the offside chamber wall rebuilt to full height. The nearside (towpath side), sees the final concrete pour and awaits the brick and blockwork to be brought up to final height.

thrust walls being restored

The ‘four corners’, i.e. thrust walls are being restored. Bricks, recovered from the original chamber walls have been cleaned up, and are being used, along with lime mortar.

The Waterway Recovery Group returned for a weekend camp at the end of November and, supported by GCS volunteers, cleared vegetation from Locks 14 and 13, in preparation for work to move down the flight.

Below:

A birds-eye view of Lock 15 before rebuilding of the chamber walls – showing the four thrust walls, haul roads and the dams each end

Grantham Canal Society volunteers continue to work every day Monday to Friday on the restoration of Lock 15. They are organised into teams – a different team each day. Some volunteers are in more than one team.

Why not join them? Even half a day helps the job along! See our homepage for details – we look forward to welcoming you!

Entry: 28th June 2016

Author & upload TJ

Edit 3rd July

training available!

After eight gruelling months of demolition we have now turned the corner and can see the rebirth of a lock which has suffered from over eighty years of neglect.

Lock 15, Woolsthorpe Middle lock, has posed many challenges for the GCS volunteers to overcome including some of the wettest weather seen for many years. Despite this, numerous volunteers have gained a new skill which, at long last, now includes bricklaying.

Part of the reason that the previous lock construction may have failed was the surprising lack of foundations. The lock walls were substantially buttressed but without there being equal pressure on both sides a number of them had fractured and hence the inner walls were leaning inwards.

The new walls will now have substantial reinforced concrete foundations which, as the inner walls are rebuilt, will be stepped so as to support the complete structure. Fortunately the four thrust walls which will ultimately support the new gates are all now fit for purpose after having been thoroughly surveyed and redressed. These will be tied into the overall structure as the rebuilding progresses.

Fortunately the four thrust walls which will ultimately support the new gates are all now fit for purpose after having been thoroughly surveyed and redressed. These will be tied into the overall structure as the rebuilding progresses.

Significant support has been given to the project by local companies who have not only supplied materials at low cost but also offered their help during the project. The GCS are grateful to Newark Concrete, Tarmac’s Barnstone Works and John A. Stephens Ltd have all supported the project.

The next task will be the purchase and laying of approximately 37,000 bricks. These will be traditional bricks which will preserve the authentic look of the lock. As one can expect there is now a need for volunteer bricklayers to assist the newly trained GCS teams, so that this work can be completed during the summer months. If you can offer some of your spare time then please email Volunteering enquiry or take a look at our volunteer section on this website.

Entry: 15th January 2016

Author & upload SS

Inception to realisation

Consider for a moment the general feeling of excitement when, in 1793, the announcement had been made that the Grantham Canal was to be built. Possibly the first thoughts of designer, William Jessop were, “well that’s another one under my belt!”; for during that year nineteen other canals had been given the go-ahead and this was to be Jessop’s seventh. In modern day terms the achievement of these early pioneers was phenomenal. The Grantham Canal, which is 33 miles long with 18 locks and over 60 bridges, was built in four years at a cost of £129,000 – £13,500,000 in today’s money.

Canal and River Trust Trustees visit

These were very turbulent times with the Anglo French wars in full progress and the battles of Trafalgar and Waterloo hadn’t yet been fought! Despite this, labour appeared relatively easy to find, albeit with 80 to 90% being of Irish descent. Thousands of Navigators, or Navvies as they became known, were employed to build the canals. They were usually camped near the section of canal they had been allocated. Most likely one of their first tasks was to set up a wood yard to process timber for planking, scaffolding and cart building. Kilns were built to fire the bricks which were often sold to local homesteads for building houses. The canal not only contributed to the prosperity of the area by encouraging trade but also brought a considerable amount of skill to the area. Once the canal was completed the builders either settled nearby or moved to the next project.

Lock 15 prior to restoration work starting

And so to our present day where numerous hours of work have already been spent on restoring one of Jessop’s locks back to its former glory. The lock concerned is Woolsthorpe Middle Lock, so named as it’s the middle lock in the Woolsthorpe Flight of seven. This will be the sixth lock to be restored on the canal and is being funded by the Heritage Lottery Fund (HLF), Canal & River Trust (CRT) and the Grantham Canal Society (GCS). Contributions have also been received from the Waste Recycling Environmental Ltd (WREN) and several generous sponsors without whom costs would have been substantially greater. Apart from missing both the top and bottom gates the lock walls were leaning inward and it was obvious that a significant amount of restoration work was necessary. Many hours had been spent planning the project by members of the CRT & GCS in order to determine the best method for this work to be carried out. The eventual and most cost effective approach was for the work to be carried out by volunteers. In this way costs would be kept to a minimum and all volunteers would be given the opportunity to learn a skill that would enable work to be continued on to the three further locks in the flight which are also in need of restoration.

Grantham Canal Society volunteer workforce briefing

The Waterway Recovery Group on site excavating the lock walls and preparing haul roads

Since July 2015, when the compound was erected and site hut installed, a team of volunteers have been on site 5 days a week under the supervision of a qualified CRT site engineer. The compound area, including a small copse of trees, had previously been cleared and prepared by a team of Waterway Recovery Group (WRG) personnel together with a large group of GCS volunteers. Further preparation work was then undertaken by GCS volunteers which, included the installation of drainage pipework and the construction of a haul roads to enable plant to work on both sides of the lock. WRG then returned to site with heavy plant to excavate the area around the lock walls so that preparation could be made for re-lining them.

Buttresses (counterforts) were found to have failed

Lock walls taken down in preparation for rebuilding

Brick cleaning; so repetitive – and as it turned out – competitive too between teams!

However, it was then found that the buttresses supporting the walls had failed, so the decision was made for them to be demolished. Whilst demolition work progressed the by-wash was constructed. This by-wash, which may not be used after the lock becomes operational, was necessary in order to circumvent the lock so that work within the lock chamber could be carried out. The lock walls have now been reduced down to approx. 1 metre high and the face of the haul roads coated with a thick layer of clay to form a dam so that the remaining walling can be removed and the lock fully drained.

GCS volunteers have been trained on site for operating mini-diggers, dumper trucks, abrasive wheels and numerous other associated equipment. Brick cleaning, a soul destroying task at the best of times, has been carried out in a thorough and professional manner. The several thousands of cleaned bricks will continue the heritage of the original builders, if not on lock 15, then certainly somewhere on the canal as work progresses.

The new bywash completed

We’re grateful for the support of volunteers of the Waterway Recovery Group